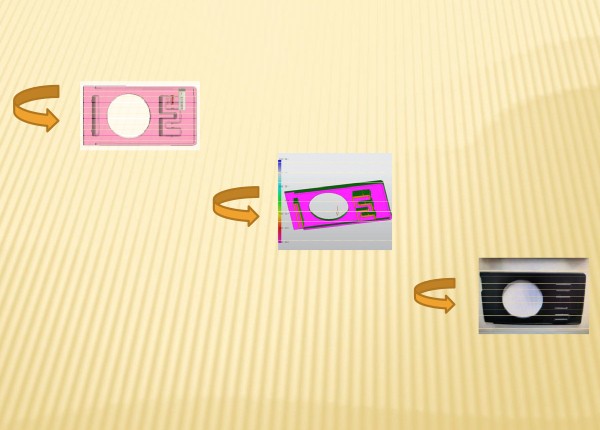

Project Optimization

Design for customers and provide part DFM and mold flow for difficult parts to check deformation and welding lines.

Design for customers and provide part DFM and mold flow for difficult parts to check deformation and welding lines.

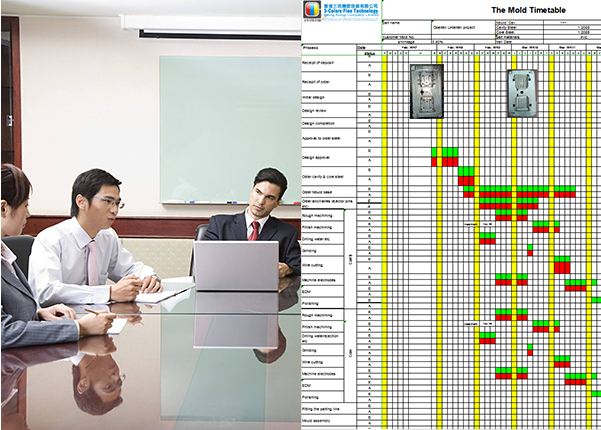

Completing your task is our great success. During the entire project operation, we work closely with tool manufacturers. In a short response time, due to the different working stages of the project, our project engineers can provide technical support for the product. Our quality control engineers also participate in inspections to solve problems before they occur. We will send timetables and photos every week for your reference, and we can provide our customers with new solutions for optimized parts design. From research and development to customer approval and production, we always work in accordance with the latest technical standards. Modern quality management and excellent customer service have always been our tenet.

The quality engineer strictly follows the ISO process and UL transportation from raw materials to tools:

Incoming material inspection, semi-finished product inspection, finished product inspection, sample inspection with EMPB report, production PPAP report, mold parts inspection. Mold inspection.